4.1.2.3 Tools(T)

PWLINK2(Lite) does not support Offline Production Program Advanced Setup, Test & Production, Super Serial Number, Device Screenshot and other features.

The Tools menu provides extended functionality for the PowerWriter® family of products and contains the following functions, as shown above and described below:

- Serial port debugging assistant: Provide PowerWriter® standard USB to serial port function.

- View PowerWriter® Interface Definitions: View port definition description information for the current device.

- View Chip Wiring Diagram: View the current chip's connection diagram reference.

- Reserved data read/write: Read/write reserved information in the device, generally used for device notes, the size of reserved data is 256 bytes.

- Offline Production Project Advanced Settings: For offline burning authority control, you can limit the UID of the target chip or the serial number of burning.

- UID Authorization Configuration Export and Load: Export the signature configuration to a file, or load the UID signature configuration information from a configuration file.

- Test and Production: PowerWriter® Production Test Plug-in.

- Super Serial Number: PowerWriter® Super Serial Number plug-in.

- Device Screenshot:PWX1 Device Screenshot Function

The device screenshot function is not open for use at this time!

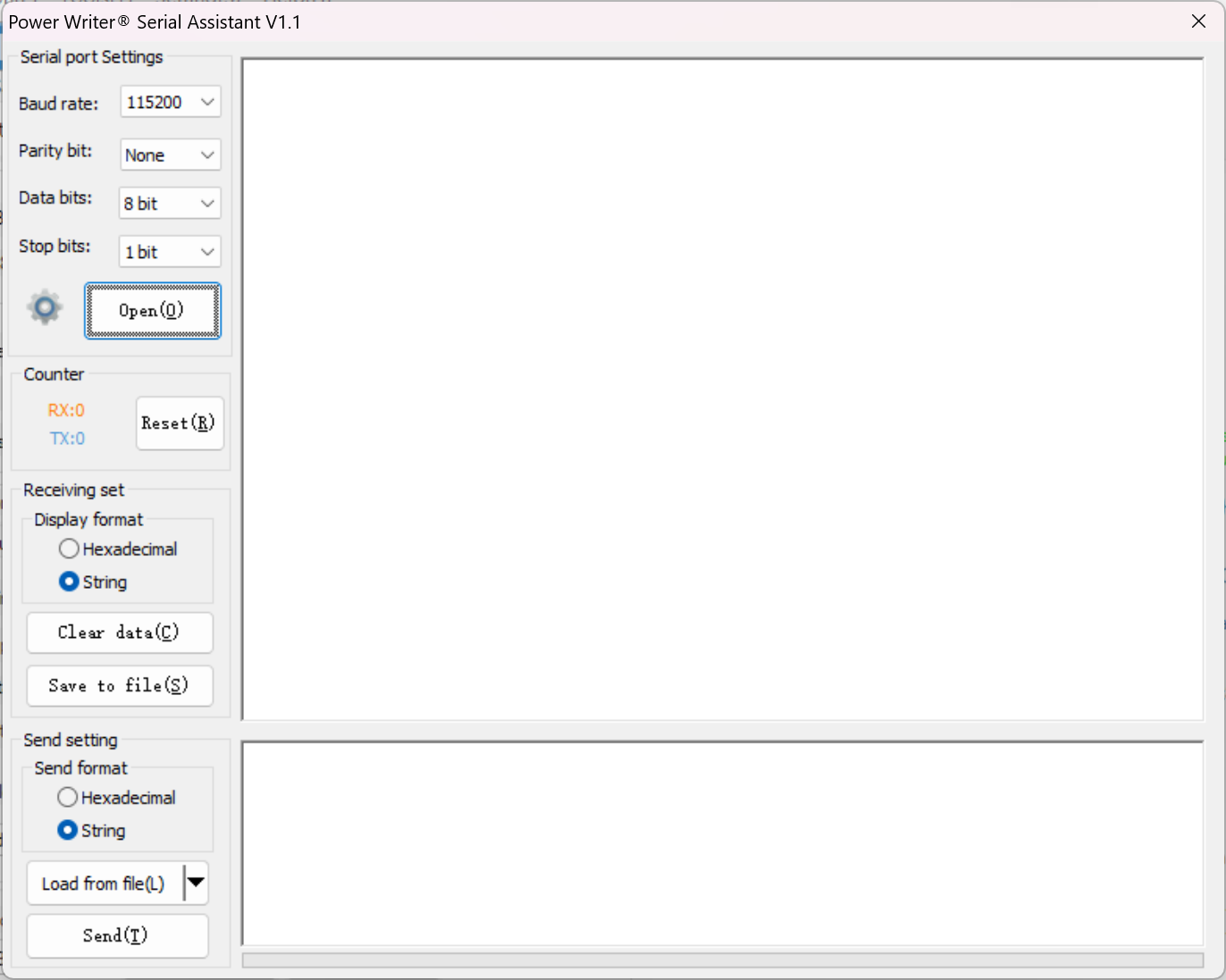

4.1.2.3.1 Serial Debugging Assistant

The PowerWriter® Serial Debugging Assistant provides standard serial assistant functionality, for additional information please refer to the How to use the serial port。

PowerWriter® can use a third-party serial port assistant, the use of the method to refer to the corresponding serial port assistant tool.

4.1.2.3.2 View the interface definition

PowerWriter® Different models of products, the same model of different hardware versions, interface signals may have differences, in general, the silkscreen on the product shell that is the correct interface signal, view the current device interface signal definition is as follows:

For detailed information on interface signals, and wiring methods, please refer to the About Wiring section for detailed information.

4.1.2.3.3 View Chip Wiring Diagram

By viewing the chip wiring diagram, you can get the connection reference information of the current chip wiring diagram, using the method flow reference: first select the chip -> then click to view the chip wiring diagram, the demonstration flow is shown below:

For detailed information on interface signals, and wiring methods, please refer to the About Wiring section for detailed information.

4.1.2.3.4 Reserve data read/write

Through the reserved data reading and writing function, you can mark the current equipment, for example, write the current project information, project check value, project use, project time information, etc., after use, you can read the equipment note information, so as to facilitate the classification of the equipment and project, commonly used in the language of the multi-device mixed for production, production control of equipment, projects and other scenarios, the use of the flow of reference is shown below:

4.1.2.3.5 Advanced settings for projects

Offline Production Project Advanced Settings, provides more offline production privilege control, including Project Notes, Burner SN Limit, UID Programming Range Limit and other functions, as described below.

- Notes within the offline file: Add notes to the PowerWriter® project file (Note: project notes follow the project file, device notes follow the device).

- Offline File Restricted Device Serial Number: restricts the PowerWriter® devices that can use the current project file; if turned on, devices outside the list will not be able to use the current project for offline programming.

- Offline File Limit UID Burning Range: Limit the range of IDs that can be burned on the target chip.

A demonstration of the function is shown below:

See below for a table of reference UIDs: UID Restriction Table.

4.1.2.3.6 UID Configuration Export and Load

The UID Authorization Configuration Export and Load function allows you to export the current signature configuration information to a file or load it from a file, the demonstration flow is shown below:

UID authorization configuration export and load function is commonly used in: ICWKEY signature lock mode and Martix signature lock mode, multiple projects share a set of signatures, or algorithms, libraries, the developer distributed to other users for secondary development, used to lock the signature information, to prevent accidental modification or exposure of the signature configuration information.

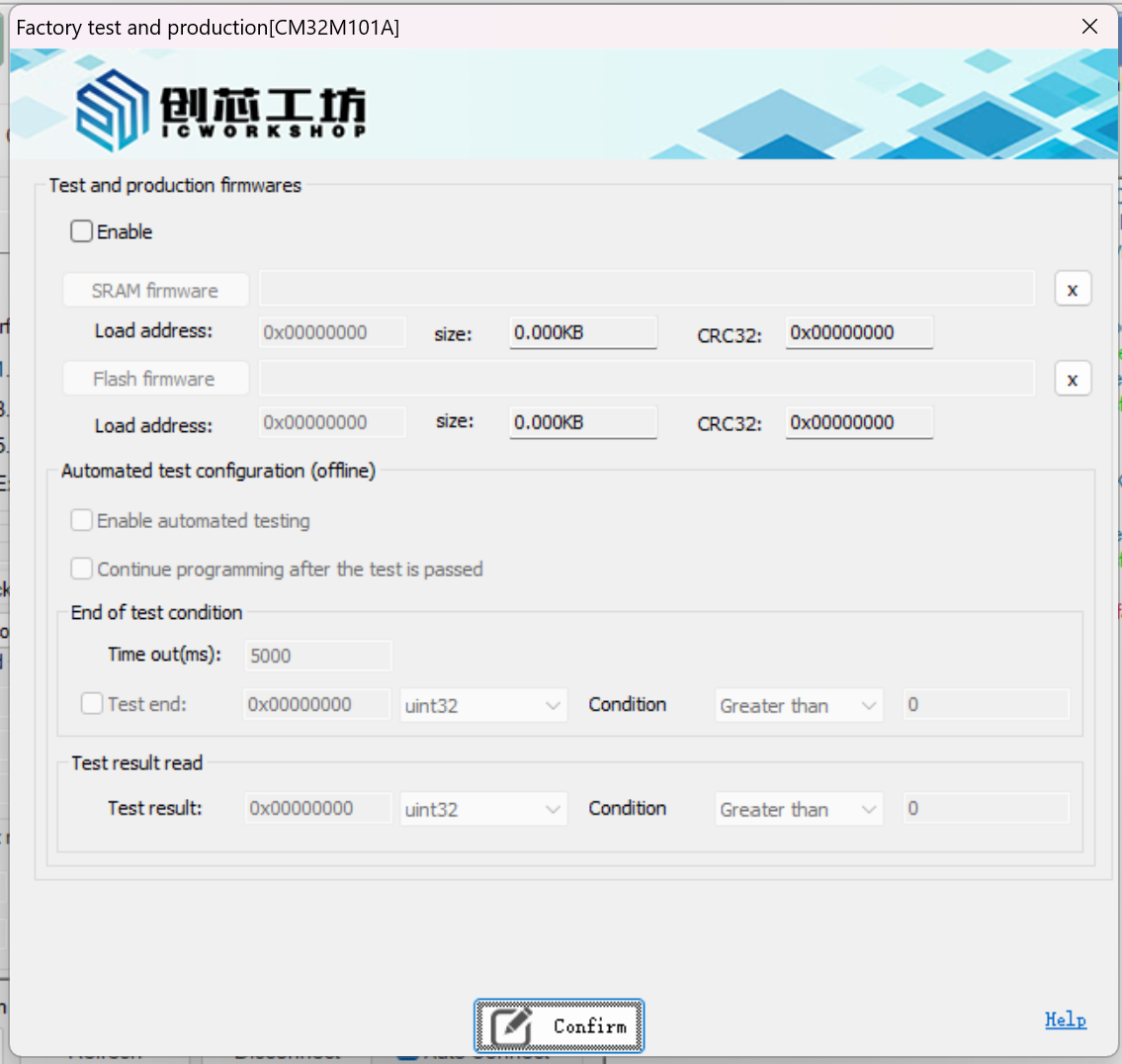

4.1.2.3.7 Testing and Production

PowerWriter® provides the target chip programming before the test and production plug-ins, commonly used in production, the target chip, the product PCB circuit board for testing, product configuration data writing and other scenarios, to change the plug-ins provide a wealth of functionality, and enough freedom to complete the production test requirements, in order to use the plug-ins more flexibly, the next step is to introduce the test and production plug-ins in the details of the use of the plug-in

- Enable: the Test & Production Functions plugin enable switch, which, when enabled, will turn on configuration options for the entire plugin.

- SRAM firmware: The test firmware can be SRAM firmware or Flash firmware. If SRAM firmware is selected, when compiling the test firmware, it needs to be compiled into SRAM, and the default is the starting address of SRAM. If compiled into other address of SRAM, it is necessary to check whether the load address is correct or not, so as to avoid that the firmware can't run correctly.

- Flash Firmware: The test firmware can be SRAM firmware or Flash firmware. If Flash firmware is selected, when compiling the test firmware, it needs to be compiled into Flash, and it defaults to the starting address of Flash. If compiled into other address of Flash, it is necessary to check whether the load address is correct or not, so as to avoid that the firmware can't run correctly.

- Enable automated testing: Enable the test function, PowerWriter® will run the added SRAM or Flash firmware, developers can develop and design their own test firmware functions, including but not limited to the target board to test, write product data, serial number, MAC address information and other functions, the test firmware after the end of the test run, the execution results are stored in the specified address, so as to allow the test process to end. so that the test process can end.

- Continue burning after the test passes: Checked: if the test passes, then continue offline programming, unchecked: after the test is finished, the test result is given.

- Test End Condition: Test End Condition Reading, store the test end condition in the specified address, PowerWriter® detects the end of the test, it will read the test result from the specified test result address, if you don't check the Test End Condition, it will read the test result according to the system timeout timeout.

- Test Result Reading: Read the test result from the specified address, when the condition is satisfied, it means the test passes, otherwise the test fails.

The operation demonstration is shown below:

- SRAM firmware will be lost at the end of the test, and Flash firmware will be stored in Flash memory at the end of the test if no erase is performed. It is necessary to select the appropriate mode according to the actual scenario, such as the two firmware colleagues add, the SRAM test firmware will be run as a priority.

- Test end conditions and test result reads can be done with a common result variable to simplify the process.

4.1.2.3.8 Super serial number

PowerWriter® Super Serial Number function, on the basis of the basic serial number function, to provide the function of custom serial number, support ultra-long shaping serial number and custom serial number import function, the use of the method is described below:

Serial Number Type: Off by default, with optional extra-long shaping (64 bytes) and external file import.

- Ultra-long shaping: set the large integer type array well, up to 64-byte sequence number length can be set

- Write address: the address to which the serial number is written

- Serial number start value: the start value of the serial number

- Serial number step: the step size of the serial number

- Serial number end value: Serial number end value

- External file import:

- Write address: the address to which the serial number is written

- Import file: Support importing serial number table from excel.

- Total number of serial numbers: the total number of serial numbers of the current file

- Starting Serial Number Offset: starting serial number index, can be modified to the desired value

- Imported serial number quantity: total number of quantities currently imported

- Write method:

- Numeric Write: Write as a numeric value

- String Write: Write as a string

- First serial number: the current first serial number value

- Ultra-long shaping: set the large integer type array well, up to 64-byte sequence number length can be set

Manufacturing datetime:

Type:

- 0-don't enable this function

- 1-(20 bytes, null endian) Write string, format YYYY-MM-DD hh:mm:ss

- 2-(8 bytes, little endian) Write BCD code, format uussmmhhDDMMYYYYY

- 3-(8 bytes, big endian) Write BCD code, format YYYYMMDDhhmmssuu

- 4-(4 bytes, little endian) Write timestamp, based on zero hour on 1 January 1970

- 5-(4 bytes,big endian) Write timestamp, based on zero hour on 1 January 1970

- 6-(8 bytes,little endian) Write timestamp, based on zero hour on 1 January 1970

- 7-(8 bytes,big endian) Write timestamp, based on zero hour on 1 January 1970.

Write address: Flash address to write real-time time 。

How to use Super Serial Number, detailed tutorial reference please refer to Super Serial Number Tutorial 。

- Currently the write time function, is limited to PWX1 devices, other devices can not be turned on by default, turned on this function, will also be ignored.

- The address is not checked for overlap, so please double check that the address and other dynamic data do not overlap (unless it is intentional).

4.1.2.3.9 Device Screenshot

The device screenshot function allows you to take a screenshot of the current device display interface, as shown above:

Current function only for PWX1 devices

Current features are not open!