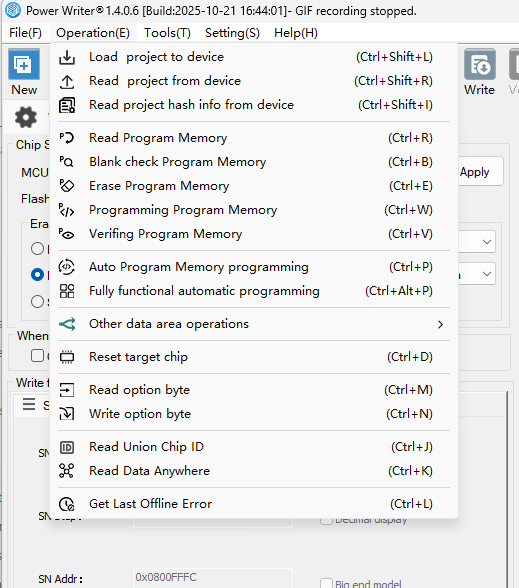

4.1.2.2 Operator(E)

PWLINK2 / PWLNIK2 Lite devices do not support the Load / Read / Read Offline Error Code function for offline items, please note that these three functions will be disabled when such devices are connected.

All functions in the Execute menu have corresponding key functions on the shortcut toolbar.

The execution function contains most of the operations of PowerWriter®, including offline loading and reading back of project files, online reading and writing operations on the target chip, The functional interface is shown in the figure below:

4.1.2.2.0 Load project to device

PWLINK2 (Lite) does not support this feature!

Through the offline loading function, the configuration data of the PowerWriter® is saved as a PowerWriter® project file and loaded into the device, and after the loading is completed, it can be burned offline, the demonstration process is shown below:

If you do not save to the project file when loading, you will be prompted to save the project to disk .

If you need to initiate offline burning, disconnect the PowerWriter® from the device!

4.1.2.2.1 Read project from device

PWLINK2 (Lite) does not support this feature!

Offline read function, you can read back the project file currently selected by the device, read back the project file, can not read back the project password, such as the project file for the encrypted project, you still need a password to open the view, the operation process is shown below:

4.1.2.2.2 Read project hash info from device

PWLINK2 (Lite) does not support this feature!

PW200 and PW300 do not have a screen. You can confirm the project information within the device by reading the engineering summary from the device. The read-back project information includes:

- Whether reading back the engineering from the device is prohibited

- The number of files added

- File 0: Address, size, CRC32, checksum

- File 1: Address, size, CRC32, checksum

The operation process is as follows:

4.1.2.2.3 Read program memory

By reading the Program Memory function, you can read the code space data of the target chip, and you can set the read address and read size when reading, and you can export the data to the disk after reading back the data, the operation demonstration flow is shown as follows:

Before executing this function, you must ensure that the target chip is connected and encryption is not turned on to operate! For more detailed operation procedure, refer to: Read chip data and save.

4.1.2.2.4 Blank Check program memory

By checking the empty Program Memory function, you can quickly check whether the target chip is a blank chip, such as checking the chip is empty, it will prompt to check the empty successfully, the demonstration flow is shown below:

Before performing this function, you must ensure that the target chip is connected and encryption is not turned on in order to operate!

4.1.2.2.5 Erase program memory

Before executing this function, you must ensure that the target chip is connected and encryption is not enabled! If you want to erase a specific page, please execute: Erase Selected Page on the Program Memory page.

Erase Program memory function, you can execute erase on the target chip, the demonstration is as follows:

4.1.2.2.6 Programing Program memory

Before performing this function, you must ensure that the target chip is connected and encryption is not turned on in order to operate!

By programming the Program memory function, the firmware loaded by the user is written to the target chip code space, and the source of the written data depends on the following two cases:

When the chip firmware (bin, hex, s19, elf) file is not added, the entire editor buffer will be written.

When a chip firmware file is added, the starting address and size of the data that is written, depends on the file that is added, but the source of the data still originates from the editor buffer, which means that there are the following states.

- When a file is added, data will be copied from the file to the buffer, and any unsaved data in the buffer will be lost.

- When reading the target chip data, the data will be copied from the target chip to the buffer, at this time, the file can be exported, such as when re-clicking the application firmware, the buffer data will be overwritten.

- When editing the buffer directly, the original firmware file will not be modified directly, and when the editing is finished, click Program Program memory to write the modified buffer data (overlap with the added file) to the target chip.

The operation demonstration flow is shown below:

tip

tipThe buffer editor serves as a staging state for the PowerWriter® to communicate with the target chip, and is applied flexibly in different scenarios.

4.1.2.2.7 Verify program memory

- Before performing this function, you must ensure that the target chip is connected and encryption is not turned on in order to operate!

- With the checksum function,data comparison can be performed directly without reading the firmware's checksum value (CRC32, Check Sum).

Through the Program memory verification function, you can compare whether the currently loaded data and the target chip are the same, before verification, please load the PowerWriter® project or add the firmware of the chip that needs to be verified for comparison, the operation flow is shown below:

4.1.2.2.8 Automatic programming

Before performing this function, you must ensure that the target chip is connected and encryption is not turned on in order to operate!

Program memory auto-programming will automatically erase, program, and verify the code space. Erase Program memory、Programming Program memory、Verify Program memory, The operation demonstration is shown below:

4.1.2.2.9 Full automatic programming

Full-featured auto-programming will automatically complete a series of processes according to the current project settings, such as writing option bytes, serial number, Matrix signature information, automatically selecting the erase method, automatically completing all the data programming, checking, and completing the subsequent actions after the end of the burn-in, such as resetting the chip to run, etc., simplifying the complexity of the process, a one-step completion of the process. In most of the time, this function can realize online one-key programming, the demonstration flow is shown below:

Full-featured auto-programming, does not support plug-in functions, such as UID restriction, SN restriction, factory test, some special chip customization plug-ins, such as STM32WB protocol stack upgrades, STM32H5 security configuration and other extended functions, if you need to perform the extended functions, please use the offline burn-in mode.

4.1.2.2.10 Other data area operations

Other data area for the dynamic data area, all the chips have Program memory area (code flash), in addition, some of the chips also contain some specific storage areas, such as EEPROM, USER DATA, OTP, BOOT and other areas, although the name of the strange, but the function is the same, is mainly divided into three types of storage areas:

- Stored data: EEPROM, USER DATA, etc.

- Stores data and can only be programmed in a single pass: OTP

- Storage code: BOOT, STACK, APP, etc.

The function of this area, the operation of the same Program Memory operation, in addition to OTP, are supported to read, check the empty, erase, program, verify and other operations, the following selection of different chips to demonstrate the dynamic tabs, as well as the function, as shown in the figure below:

OTP does not support erasure: it means that it is not possible to reprogram the same address!

4.1.2.2.11 Reset Target Chip

Performs a reset operation on the currently connected target chip, the reset will release the connection to allow the target chip to operate, the target chip reset, there are a variety of modes to choose from, for details, see the selection of the reset mode in the signal output control, see the figure below:

4.1.2.2.12 Read option byte

Before performing this function, you must ensure that the target chip is connected and encryption is not turned on in order to operate!

Through this function, you can read the option bytes of the current target chip back to the PowerWriter® application, which is commonly used to check the configuration, read protection, write protection and other information of the current chip, the operation demonstration is shown below:

4.1.2.2.13 Write option byte

Before performing this function, you must ensure that the target chip is connected and encryption is not turned on in order to operate!

Write the current option word, to the target chip, as demonstrated below:

4.1.2.2.14 Read CID

By reading the CID interface, the ID information of the current target chip can be read and displayed in the log column as follows:

Chip ID addresses are not consistent from one chip to another, and there are chips without IDs or chips with undisclosed ID information!

4.1.2.2.15 Read data from free address

Arbitrary address read data function, can read the data in the non-secure, isolated area of the chip, including SRAM, Flash, peripheral registers, etc., the operation demonstration is shown below:

The data in the isolated and safe area requires special operation to access, and the isolated area operation is not supported at the moment.

4.1.2.2.16 Get last error

PWLINK2 (Lite) does not support this feature!

Through this function, you can query the last offline operation result of PW200, PW300, PW400, etc., in order to troubleshoot the offline burning abnormality problem, as shown in the following demo:

This error code, which is only overwritten and updated when a new offline burn-in is performed, is not cleared by powering down the device, or by in-line programming operations!